The climate crises presents a huge challenge to us all. Changes are needed at Governmental levels, but businesses can do a lot to make a difference.

One crucial change that is needed is to fully embrace and adopt Circular Economy principles.

Legislative changes and customer requirements are placing greater emphasis on lighting that is truly sustainable – products that are not just energy efficient, but which are also resource efficient. As a result, we need to keep products in use for longer, rather than simply discarding them, or needlessly recycling them.

At Recolight, we recycle, but recycling is not always the best solution as we move towards a Circular Economy model.

.

-

- Resource depletion will begin to drive up the cost of raw materials, leading to more use of recycled materials.

- A route for fixtures to enjoy further lives after the original installation is a natural conclusion for Circular Economy adoption.

- New services are available to facilitate the re-use and repair of fittings. Re-manufacturers have indicated they will provide warranties and certification of reused product.

-

- There is an emerging opportunity for maintenance and manufacturing companies to offer re-manufacture or reconditioning services.

- Specifiers have a crucial role to play in educating end users about the importance of using products which embody Circular Economy principles.

- Reforms to the WEEE Regulations will incentivise re-use, and circular business models. Defra is considering setting separate targets for re-use.

Accelerating uptake of Circular Economy

Recolight has worked with the lighting industry for several years to help drive adoption of the Circular Economy. The company has launched key initiatives to provide information, practical guidance, and services.

WEBINARS

Recolight webinars focus on the Circular Economy. With over 50 presenters, from across the lighting industry, we have learnt that our industry needs to do far more to be genuinely sustainable.

CIRCULAR LIGHTING LIVE

One-day conference and exhibition, bringing together leading experts and policy makers. Key takeaways are: forthcoming standards and legislation, emerging technologies and new circular economy business models.

REMANUFACTURING LIGHTING

An in-person training workshop to help organisations learn how to set up a remanufacturing service.

CIRCULAR LIGHTING REPORT

The industry’s online hub for all sustainability matters, edited by Ray Molony. It brings together sustainability news, interviews, and updates from across the lighting industry.

REUSE HUB

Reuse of used lighting: To help encourage re-use, rather than recycling, we can provide data regarding used fittings being removed to potential remanufacturers. Fittings can be delivered free of charge to remanufacturers in the UK. The remanufacturer takes ownership and responsibility for product thereafter including compliance.

Surplus new lighting: Many manufacturers hold unsold stock. Recolight make it easy for a manufacturer to hand over new surplus lighting to third-parties that can put the product to good use.

LIGHTING AND SUSTAINABILITY

Lighting has done a lot to promote sustainability. LED products have longer lifetimes, greater system efficacies, are more flexible and controllable, and vitally do not contain mercury.

-

- An increasing number of organisations are willing to specify used/reconditioned lighting equipment.

- More lighting manufacturers are engaged in remanufacture of used fittings as a business opportunity.

- More organisations of all types are implementing net zero plans.

There is still a great deal that we must all do but it is good to recognise that change is in the air.

Protecting the environment

The reuse or disposal of end-of-life equipment should be an integral part of all LED luminaire replacement projects. Not just for legislative compliance, but also to meet the sustainability and corporate social responsibility requirements.

To increase the reuse and recycling rates specifiers should insist that producers take responsibility for recycling of the waste luminaires that arise. An even better environmental outcome is for the luminaires to be LED retrofitted in situ.

End users want to know more than just how the lighting will be reused or recycled. Increasingly, they are asking producers for the percentage of components and complete fittings that can be recycled, and the percentage of recycled material used in the manufacture.

RECYCLING

Where reuse is not possible, for technical or commercial reasons, recycling is the next best option.

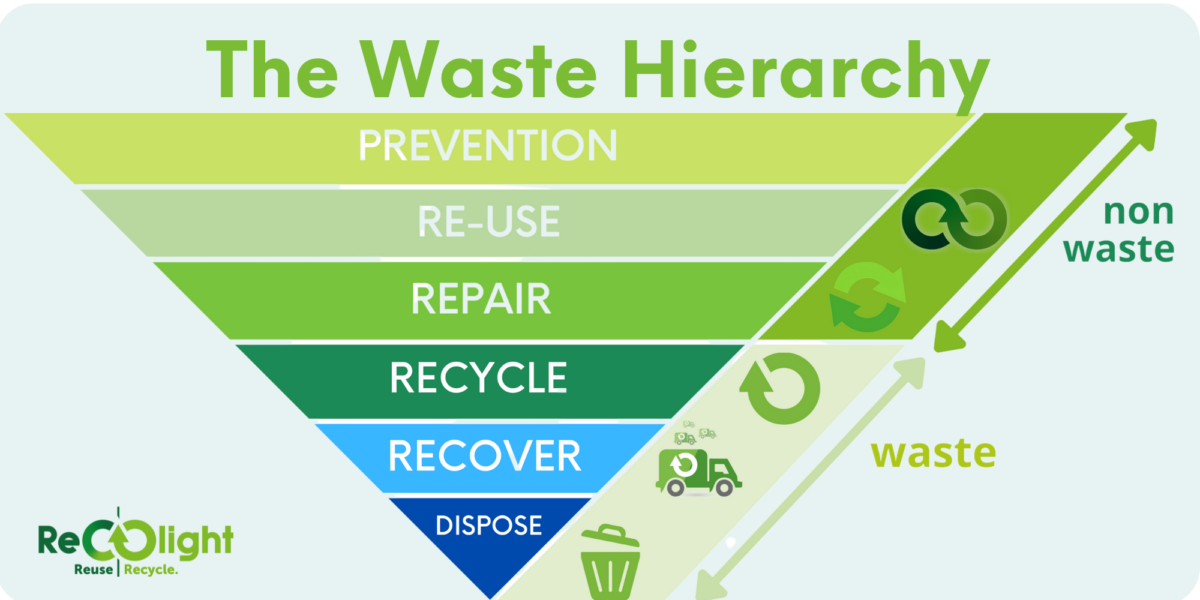

The waste hierarchy quite rightly puts recycling below prevention, repair, and reuse. To drive improved sustainability in the lighting sector, we must get much better at applying the waste hierarchy. That means prioritising repair and reuse above recycling. Historically in our industry, we have regarded getting waste recycled as good enough. We need to change that mentality.

Lamp recycling rates in the UK have grown faster than any other waste electrical equipment category; from 19% in 2008, to 43.1% in 2020, and 68% in 2023. The lighting industry is unique in taking such an effective, sector specific approach to waste and recycling. Electrical contractors, wholesalers and lighting manufacturers can be proud of this recycling record and contribution to sustainability.

Recolight’s recycling and recovery rate

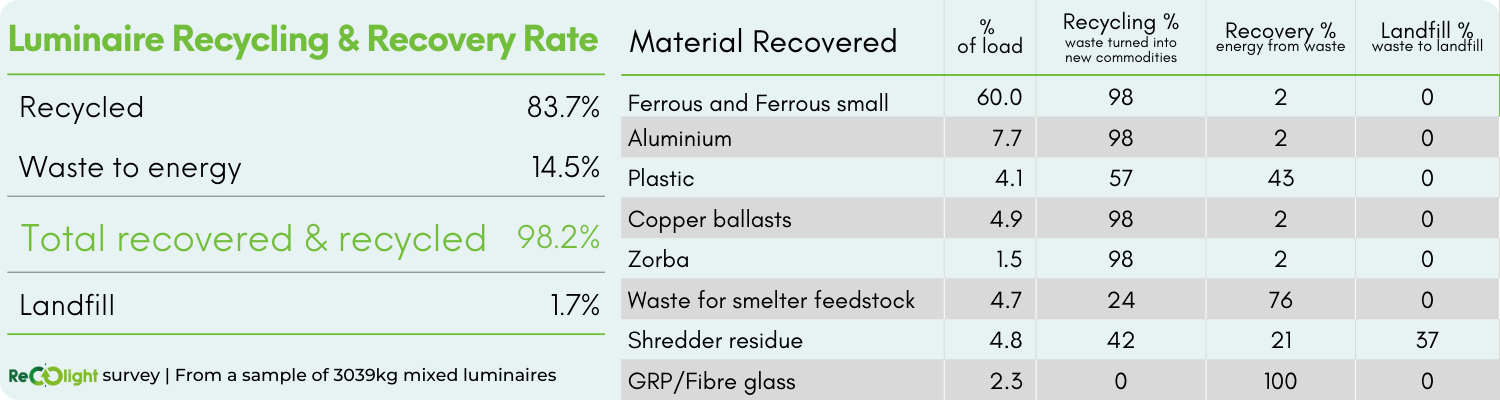

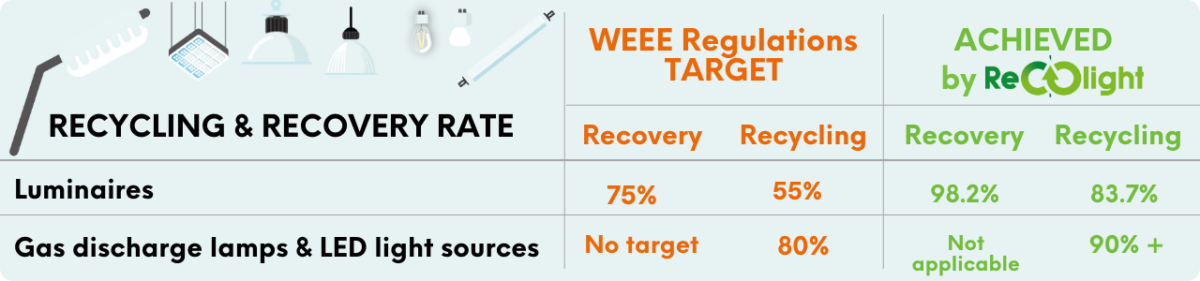

The WEEE regulations set a target for recovery and recycling that must be achieved by an Approved Authorised Treatment Facility (AATF).

The recycling rate achieved by Recolight’s contracted recyclers comfortably exceed the recycling and recovery requirements set in the WEEE regulations:

Recycling rate: Percentage of material recovered during the recycling process.

Recovery rate: Percentage of material recovered including energy recovery during the recycling process.

Luminaire recycling and recovery rate

The breakdown of raw materials recovered after treatment of a typical load of luminaires has been independently assessed: