Trilux unveils moisture-proof light made from recycled plastic

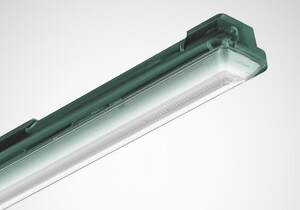

Trilux has unveiled a version of its Oleveon Fit and Aragon Fit moisture-proof luminaire whose diffuser and housing is made from 100 per cent recycled plastic.

The light fitting, developed over 14 months by its subsidiary Zalux in Spain, ‘does not compromise efficiency, light quality or robustness,’ said Manuel Pina, sustainability director at the firm, who led the development.

Two types of recycled plastic are used for the sustainable luminaires. To meet the high demands placed on the optical system, the diffuser is made of post-industrial polycarbonate, sourced from production waste in the automotive and consumer electronics industries, such as headlights or monitor covers. Meanwhile, the housing is manufactured from post-consumer polycarbonate, which is made from recycled, shredded green PE bottles.

This material gives the housing a subtle, translucent green tint, highlighting the sustainability of the luminaires and distinguishing them from the classic portfolio. To make ordering straightforward, these variants are identified with the ‘RCY’ label.

The recycled raw materials are supplied in pellet form, which is fed into the production process without any adjustments. This enables production capacities to be adapted quickly and easily, says Zalux.

The company says there’s a growing demand for products like this. ‘Concrete customer inquiries have encouraged us to fast-track the development’, confirms Pina.

Last month Trilux was awarded the prestigious EcoVadis Platinum rating for its commitment to sustainability, social responsibility and corporate ethics.

EcoVadis is one of the world’s most respected providers of sustainability ratings, evaluating companies across key areas, including environmental impact, labour and human rights, sustainable procurement, and ethical business practices.

Achieving Platinum status puts the German luminaire maker in the top 1 per cent of all assessed companies. In 2017 Trilux launched the innovative Repro-Light project to support the European lighting industry in moving towards a more sustainable and competitive future by investigating sustainability, the circular economy, the modularisation of luminaires and a smart production scheme. The project led to Trilux learning from other industries and looked for more sustainable, biodegradable materials.

It was among the first lighting brands to explore the use of polylactic acid (PLA) for luminaire housing. PLA is a synthetic polymer-based on lactic acid and obtained in an environmentally friendly way from corn starch.

The biocompatible thermoplastic is suitable for producing the luminaire body using a 3-D printing process. With GRAFT Architects, Trilux took its continuous light line, Parelia LED, and constructed the main body from PLA.

Thanks to its high-efficiency lighting technology and optics, it generates glare-free quality light with 80 per cent indirect light.

In 2021, the Paralia won both a prestigious Gold and Green Build Back Better Award for the product.

• Learn more about sustainable lighting at Circular Lighting Live 2025, Recolight’s flagship conference and exhibition, which takes place on Thursday 25 September 2025 at the Minster Building in the City of London. Free to specifiers, Circular Lighting Live 2025 will feature leading experts, specifiers and policy makers who will share their insights into forthcoming standards and legislation, emerging technologies and new business models. More info: www.circularlighting.live