THE REUSE of over 5,000 existing luminaires at Shell’s headquarters in London has saved the company the equivalent of 71 tonnes of carbon compared to a replacement.

The petrochemical giant wanted to upgrade the 10 year old fluorescent luminaires at the 26 storey building to maximise energy savings.

The petrochemical giant wanted to upgrade the 10 year old fluorescent luminaires at the 26 storey building to maximise energy savings.

UK luminaire maker Future Designs, the original supplier of the bespoke luminaires, suggested that an upgrade of the lights would be the most sustainable option.

The company originally designed the bespoke luminaire to be integrated as part of the chilled beam system. Ten years on, Future Designs removed the fluorescent luminaire in its entirety and refurbished it to provide a compliant LED luminaire.

After reconditioning and upgrading, the fittings were photometrically tested to ensure the correct light levels and control.

The swap-out delivered a significant power, financial and carbon reduction.

The company calculated that reusing the luminaire housing saved 38.4 tonnes of steel being produced. This equates to 71 tonnes of carbon, the equivalent, says Future Designs, of toasting over 9 million slices of bread.

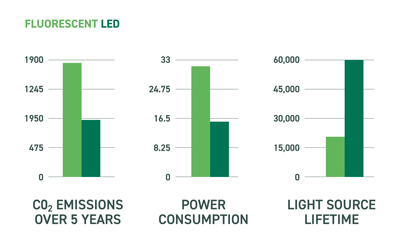

Switching to LED substantially reduced Shell’s energy consumption at the building.

A reduction of 50 per cent in energy use results in a saving of 936 tonnes of carbon over a five-year period.

As well as an LED upgrade for the main office luminaires, Future restored and upgraded the company’s original heritage chandeliers.

As well as an LED upgrade for the main office luminaires, Future restored and upgraded the company’s original heritage chandeliers.

It carried out a delicate and sympathetic restoration of six historic and architecturally important chandeliers.

In storage for many years, the chandeliers were in poor condition and required a full strip down to their component parts.

Due to the fragile nature of the chandelier and site access restrictions, bespoke transit crates were manufactured to transport the chandeliers back to Future Designs’ factory outside London.

The crates were designed to allow for two scissor lifts to raise the chandeliers, still in their crate, into place and allow for connection to the ceiling support plate. Once supported, the crates were simply lowered leaving the finished chandelier suspended.

Each chandelier was sandblasted back to bare metal to allow for inspection and local repairs.

The decorative brass louvred ceiling rose was a key feature in the aesthetics of the chandelier but sadly had sustained much damage over the years. Future technicians restored them using handmade brass parts where necessary, while maintaining as much of the original material as possible.

The circumference of the chandelier is adorned with solid glass rods. Rods were inspected for damage before being hand polished back to their original finish.

New wiring looms were designed to allow for dual switching to operate the bespoke LED lighting system.

The fittings were in poor condition after years in storage.