BS8887 | Recolight welcome new code of practice for lighting remanufacture

Recolight warmly welcome the publication of the new code of practice for the remanufacture of lighting equipment, published by BSI this month.

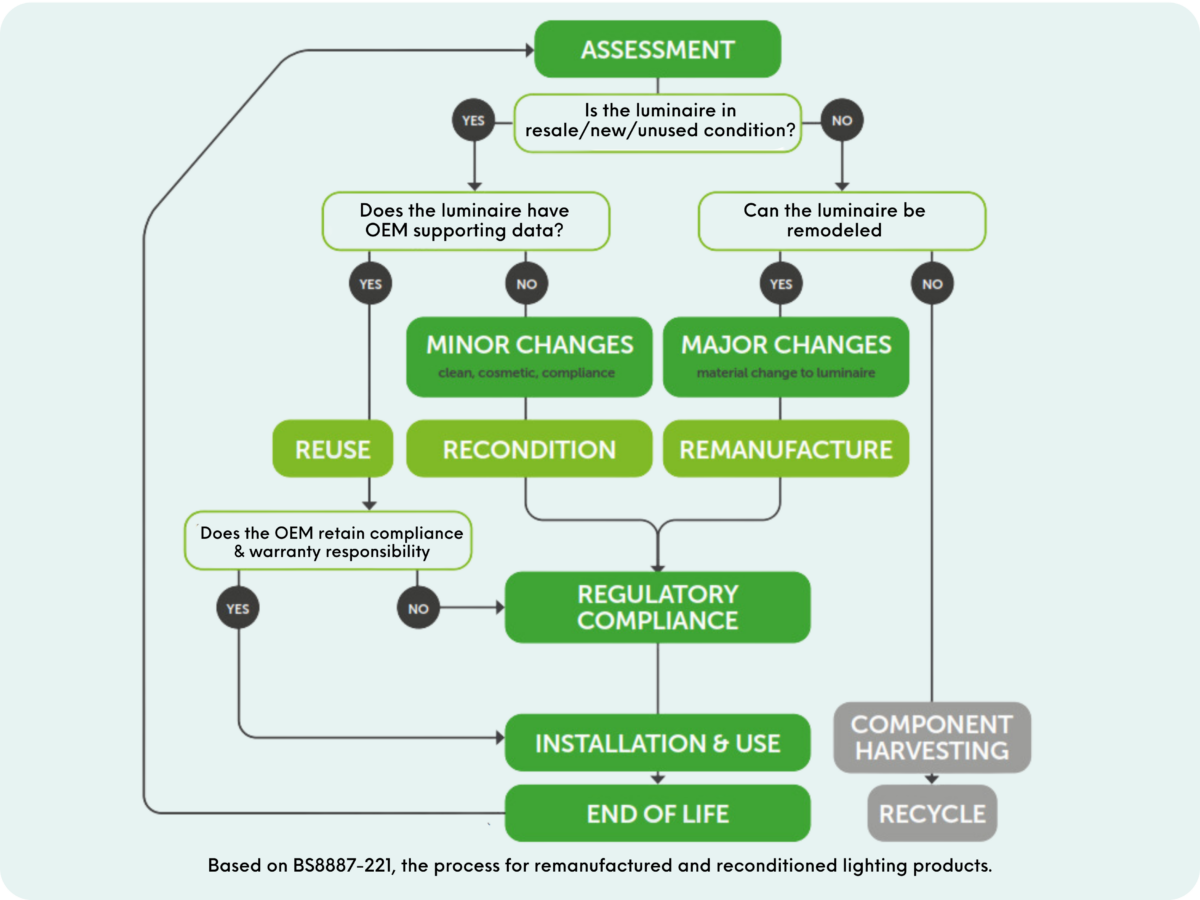

The new publication is numbered BS8887:221 2024 and is now available from BSI. The document provides a structured approach to the assessment of used luminaires and components, defining a scope of works, electrical and mechanical remanufacture, component selection, markings and instructions, and testing/validation.

Commenting on the news, Recolight CEO Nigel Harvey said

“The specification is a major step forward, helping to normalise the remanufacture of lighting equipment. First and foremost, it should give confidence to specifiers, end users, and producers that luminaires remanufactured in accordance with the requirements are compliant and fit for purpose.”

He added

“This code of practice has been developed thanks to the hard work and dedication of the drafting committee. Particular thanks go to the Committee Chairman Tom Ruddle, formerly Remanufacturing Engineer at Egg Lighting. He was instrumental in keeping the team, and the project, firmly on track.”

The specification was developed over some two years, including representatives from lighting manufacturers, luminaire designers, lighting designers, the Lighting Industry Association, and Recolight.

Remanufacture is a vital way in which producers and end users can better embrace a circular economy, by keeping products (or parts of products) in service for longer. It is the logical application of the “Reduce – Reuse – Recycle” hierarchy to the lighting industry. Typical embodied carbon savings from remanufactured products are 50-80% compared to new products, with similar levels of waste avoidance.

An increasing number of UK lighting companies are now engaging in remanufacture. One of the most common approaches is to retrofit fluorescent luminaires with LED light sources, thus retaining the body of the luminaire. Such remanufacturing operations can either take place in a producer’s factory, or can also take place at a customer site.

It is important to note that BS8887 is not a safety standard, and compliance with it does not eliminate the need to apply safety and other standards.