Microprisms are made from 90% recycled acrylic

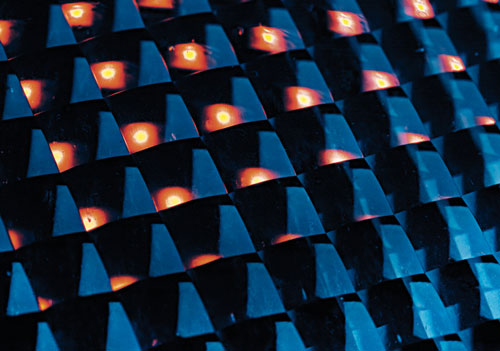

A SWISS firm has unveiled a series of sustainable microprismatics for luminaire optics made from 90 per cent recycled PMMA.

Zurich-based Jungbecker says its Greenline will make an important contribution to sustainability in the lighting industry.

Crucially, the hot-embossed microstructures made from recyclate retain the highly transparent prism surfaces and suffer no loss of quality and performance, says the company.

Additionally, all waste generated during the production phase in reprocessed into reusable raw materials.

PMMA, or poly methyl methacrylate, is an engineering plastic also known as acrylic or acrylic glass and is widely used in the lighting industry.

It has a range of key properties: it’s lightweight, shatter-resistant, translucent and has half the mass of glass.

It transmits up to 92 per cent of visible light (3 mm thickness), and gives a reflection of about 4 per cent from each of its surfaces due to its refractive index.

It is used in car headlights, aircraft windows and even in the transparent shields of riot police.

PMMA’s attributes cannot be easily replicated which is why a sustainable option is significant as lighting manufacturers chase better sustainability and embodied carbon metrics.

Jungbecker is an established supplier the lighting, electronic and automotive industries and sells micro structured special optics for louvers, cars and aerospace applications.

It specialises in optics for diffusion, glare reduction and light-guide applications, allowing for greater flexibility to adapt to changing LED technology and design specifications.

Jungbeckers’ products can be used in both backlit and edge-lit LED applications.

The microprismatic surfaces allow the light to be concentrated, guided and shaped for glare-free light panels and lenses for both interiors and exterior environments.

The Greenline range is distributed in Europe by Switzerland-based Inter Tek Trading and in north America by New Jersey-based Evonik Cyro.