Mobile lamp crushing

When waste lamps are collected they are usually transported whole, in their collection container, to a treatment plant. But as an alternative, they can be crushed at the collection site, and then transported in sealed packaging to a treatment plant.

When tendering, Recolight does not differentiate between the two approaches. We consider both acceptable alternatives. We want as much choice as possible in the selection of transport and treatment partners. There are inevitably situations in which one approach is favoured over another. For example, where sites collect very large quantities of waste lamps, whole lamp transport is often preferable. Conversely, sites with physical access restrictions may benefit from the smaller vans that mobile crushing can use – no need for an articulated lorry to manoeuvre into place.

DEFRA recently ran a consultation on mobile crushing. Following an analysis of responses, they have decided to put in place a permitting regime for mobile lamp crushing (see consultation outcome). At Recolight, we think DEFRA have reached the right decision on this issue. The new regime will extend the situations in which mobile crushing can be used, whilst putting in place proportionate controls. At the same time, DEFRA will continue to allow companies to use their own crushing equipment, on their own premises, to crush their own waste lamps.

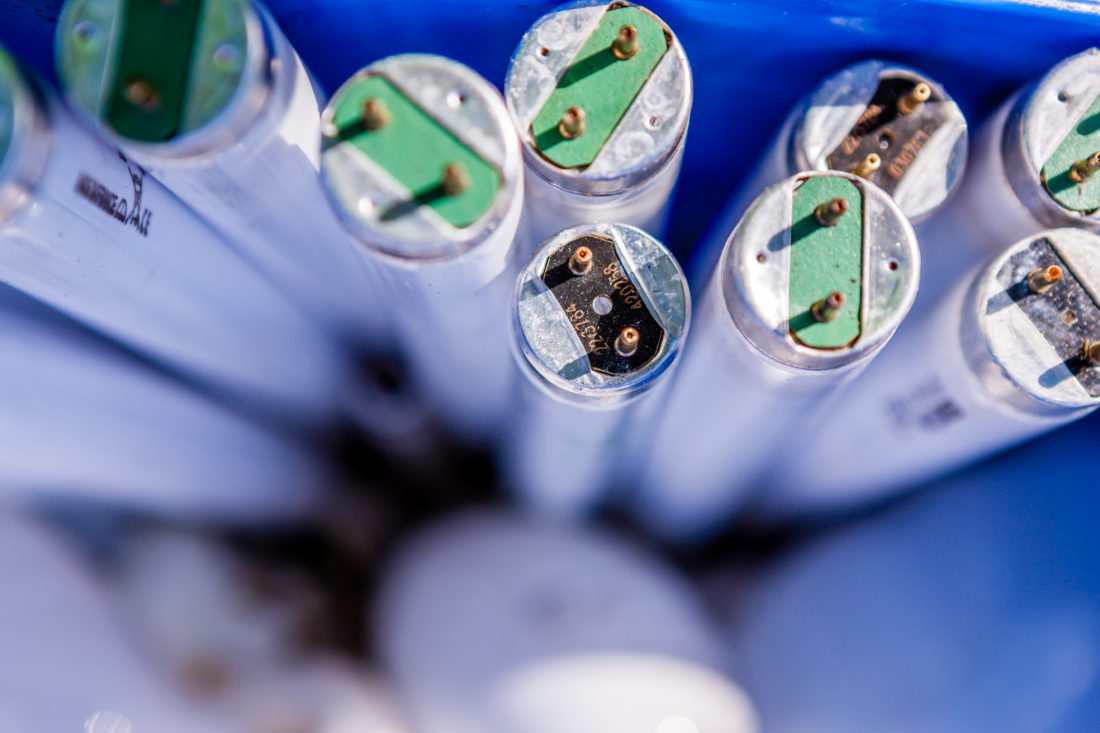

It is common for waste lamp containers to be poorly stacked, transporting them intact can result in lamp breakage, and hence mercury release. Recolight use mercury vapour detection equipment and we are entirely satisfied that the mobile crushing we contract does not result in mercury release.

For more information on good lamp storage please see our guidance.