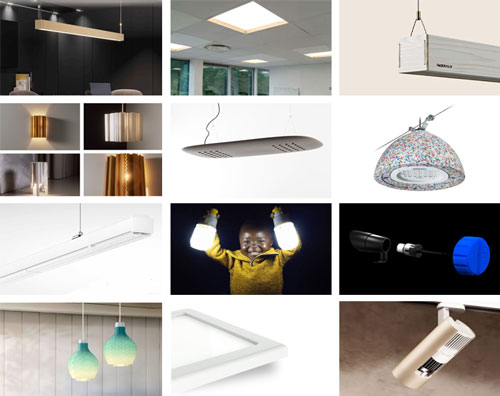

12 luminaires from the future

Circular Lighting Report editor Ray Molony selects a dozen exemplars of low impact lighting which challenge the current take-make-waste norms of luminaire manufacturing and point to an alternative sustainable future. These inspiring developments in materials, modularity, upgradability, replaceability, demountability, and reuse point to a future where the lighting industry addresses its responsibilities towards the planet and its climate. They point to an exciting future where luminaires are made from sustainable materials to innovative designs that take into account their environmental impact.

Lightly Butterfly

This sober looking luminaire is actually pretty radical.The body is made from wood from Poplar trees. The end caps are wood, with wool felt for the gaskets. The suspension is hemp. And it’s held together with beech dowels. Not a component you see in many luminaire factories. The housing is completely free of metal, plastic and glass.

But probably the most radical bit is its lack of a diffusers. Instead the light distribution is created by the internal profile shape of the fixture itself.

It has the internal shape of a butterfly, and it creates a butterfly shaped light distribution. There are two LED boards mounted on these shelves giving an 80 up/20 down distribution. The profile is finished in highly reflective eco-friendly paint. The driver is housed remotely in a metal box. The company says the Butterfly luminaire is 95 per cent biodegradable, 3 per cent recyclable and a mere 2 per cent goes to landfill.

Kraken luminaire

This French luminaire maker is taking things one step further. This 600×600 modular is from a firm near Nantes called Kraken. It uses wood but this time wood from reclaimed windows and doors. The founder Nicolas Forget says this is a rare differentiator in a crowded market. He says he was also keen to use reclaimed on a technical commercial luminaire rather than a decorative.

This is an installation at a multidisciplinary engineering consultancy also in Nantes.

Fagerhult Kvisten

The Kvisten from Fagerhult has a body made of pine plywood sheets with an outer layer of birch. The company says that the luminaire has passed 0-95 per cent humidity testing and the 650C glow wire test and has full third party accredited ENEC safety tests. It has milled endcaps which means that only five safety screws are required for the complete fixture.The reflectors are made from discarded television sets and the louvre has by 50 per cent less plastic compared to the company’s standard microprism. Only 180g of virgin plastic is used in each fixture. It delivers all the usual numbers you’d associate with a Fagerhult product: an efficacy of up to 144 lm/w and UGR of 19. It comes in direct or direct/indirect lighting options and is compatible with Organic Response lighting control

Signify Coastal Breeze

This is the Coastal Breeze range from Signify. These are 3D printed to order in Belgium using what’s termed ocean plastic. Up to 46 per cent of ocean plastic is made up of fishing nets, lines and ropes. from discarded fishing nets. These nets are lost or discarded in the sea, endangering the lives of marine wildlife. The plastic is sourced from Fishy Filaments, a Cornish company which transforms this waste into granulate ready for 3D printing. It uses around 4.5 metres of fishing net per luminaire. Signify says that 3D-printed luminaires represent up to 76 per cent lower emissions from material supply and manufacturing, and up to 28 per cent savings in transport.

Delta Light High Profile

Here Delta Light has teamed up with Dutch architecture firm MVRDV to create a range of luminaires made from waste offcuts of aluminium extrusions. It’s called the High Profile series (geddit?) and it includes pendants, wall fittings and freestanding luminaires. The idea is for the form to be out and proud so to speak rather than hidden inside a luminaire. They soften the industrial look by giving the profiles a colour dip in colours such as in pink, green and blue.

Artemide ALE

Another offering from a big brand, this time Italian company Artemide. This is a suspension luminaire called the Adaptive Lighting Experience. The shell is made from 30 per cent natural wood fibres mixed with a base of bio-based or recycled polymers. The wood is waste from the production of bottle stoppers for the spirits industry. Not sure if the Artemide engineers have to drink the spirits.

Lorelux exterior luminaires

Another offering from an Italian company, a Lombardy company called Lorelux. This is range of street and urban lights made from 98 per cent post-consumer plastic waste. With this luminaire the company makes a positive of the multicoloured effect of the reused plastic, in this case caused by bottle caps. The company says it’s done an LCA study which showed that used post consumer waste reduced raw material extraction by 15 Kg for each fitting.

Shoplight Nort

The body of the Nort spotlight is made with plant-based polymers rather than aluminium. The company has also invested in its own 3devo shredder for recycling the surplus plastic from the production of the Nort. It is also promising a take-back scheme for its bioplastic products, including the Nort.

It says it can reuse all major components and reform the plastic back into new products. It’s also boasts a patented cooling system to take the heat away from the LED sources.

Trilux E-Line

Trilux has gone back to the drawing board with the new E-Line and looked at every detail. Instead of one eye-catching element, the company has used lots of iterative measures to reduced the environmental impact of the luminaire by than 61 per cent better.For instance there’s an imaginative packaging and transportation system which has saved 9.7 tons of Styrofoam and 95 tons of cardboard. You can upgrade an old school T5 or T8 to E-Line NEXT LED in just 44 seconds without tools.

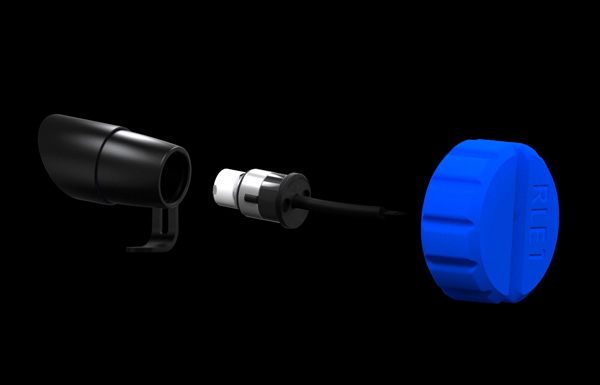

Lightgraphix RLE

UK firm Lightgraphix has introduced a replaceable light engine service for 18 of its leading products. The RLE system gives customers with the ability to repair and upgrade LED fittings at any stage in their lifecycle, renewing them for decades, with minimal material waste as a result. You can return the old engine inserts to Lightgraphix for recycling. The company says it’s the first manufacturer to implement this kind of innovation across a miniature range of exterior products, which maintain an IP67 rating.

The Chigubu lantern

The lights are completely made from waste water bottles, waste LED boards and waste batteries. It’s a project run by engineer Aluwaine Manyonga, a former SLL Young Lighter of the Year. The country has quantities of waste LED boards from poor lighting solutions that have been introduced into Zimbabwe in recent years. The boards are rescued from luminaires where usually the drivers have failed. Manyonga and his team then pairs them with components from power banks, chargers and lithium batteries from consumer electronics to create the lamp. The full network set up consists of solar panels, DC LED luminaires, charge controllers, batteries and charging points (5V and 12V) for charging individual Chigubhu Lanterns. Manyonga has now got a training programme for would-be lighting engineers as well as a network of waste collection points.

Brighteco repurposed computer screens

Swedish company Brighteco manufactures panel luminaires from flat screens sourced from waste and recycling centres. The fully serviceable light panels are sold on a subscription, lighting-as-a-service model and the company also takes responsibility for upgrading if necessary, as well as the reuse or recycling of the products at the end of their life. Pictured is an installation of the light fittings at a school in Skärplinge, Sweden, for which the school pays a monthly fee.